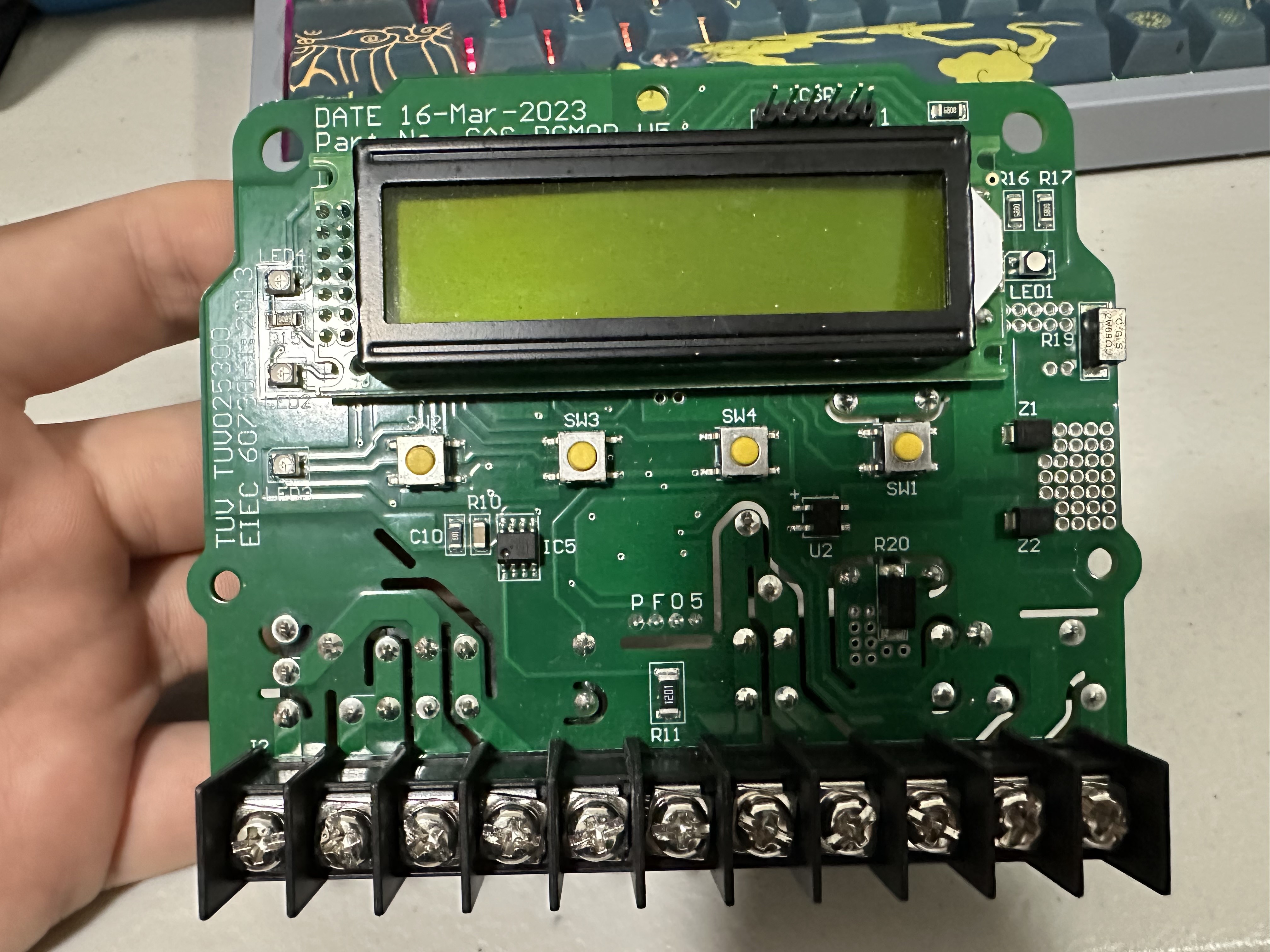

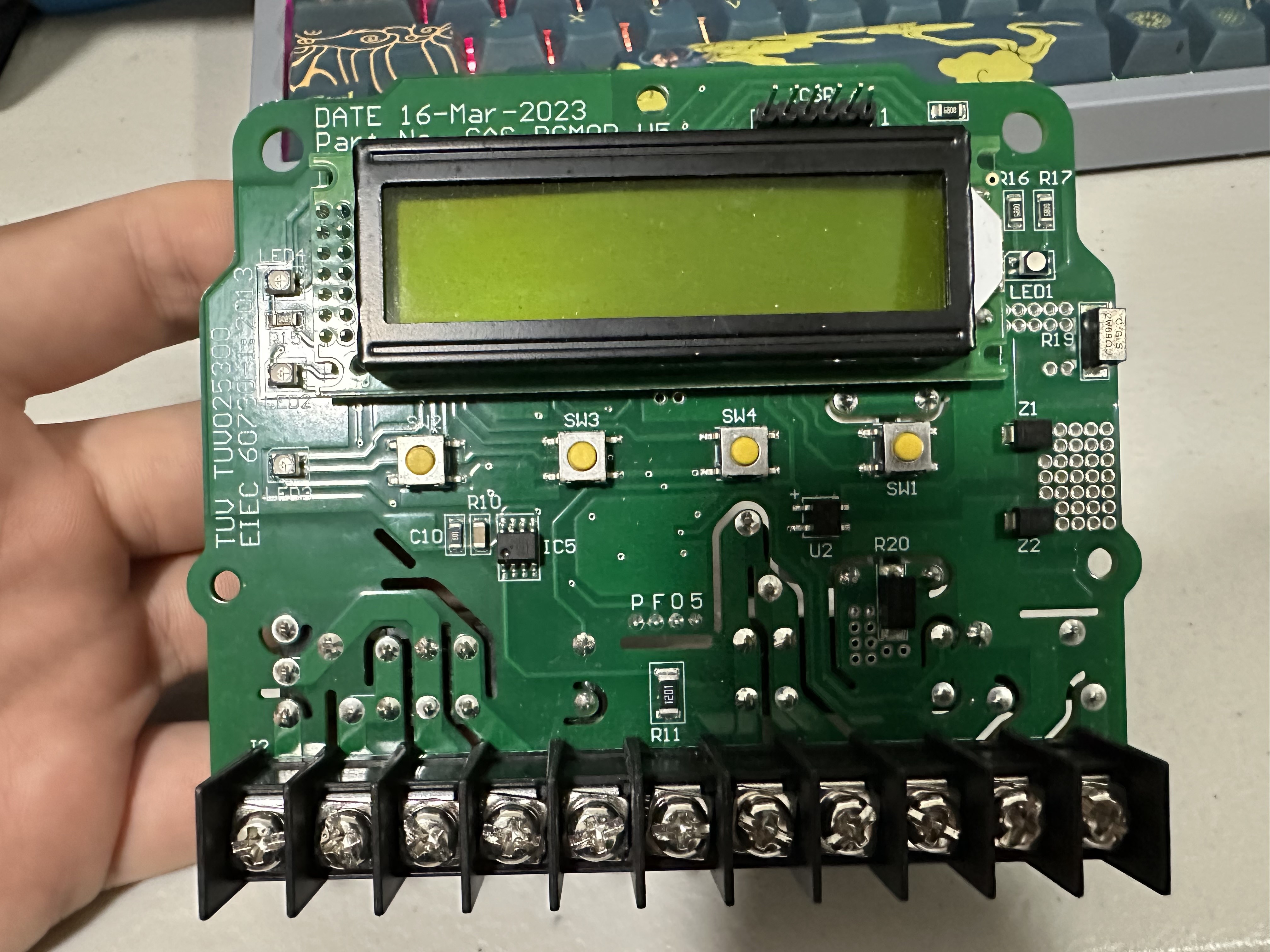

PCB Design and Firmware Production

I also take responsible for creating the firmware for the pump controller.

In this one, they use the PIC18F67K22 of Microchip. Before, the firmware was made by the

PIC block programming, it consumes a lot of memory which is 80%. When I create the firmware

with MPLab IDE in C language, it reduce to 40% of total memory. Overall, re-creating the firmware

in a universal language such as C helps to reduce the cost for the MCU, and making the firmware

maintainance and update easier for the future engineer.