This is a custom bed slinger 3d printer that I designed and built by myself (2021)

Objective: Why a new 3d printer?

Initially, the 3D printer available in Vietnam within the $200 price range in 2021 lacked dual lead screws for the Z-axis. This resulted in a critical issue where the X gantry without the lead screw would tilt downward. Consequently, the X gantry no longer maintained parallel alignment with the bed surface.

Furthermore, during that timeframe, 3D printers were suboptimal for running a 3D printing farm due to challenges in finding replacement parts. However, having a 3D printer constructed with open-build components makes it much easier to replace parts in the event of malfunctions.

In conclusion, this presents a valuable opportunity for a second-year mechatronic student like myself to delve into additive manufacturing technology. It allows me to gain hands-on experience in configuring firmware and mastering 3D modeling with SolidWorks.

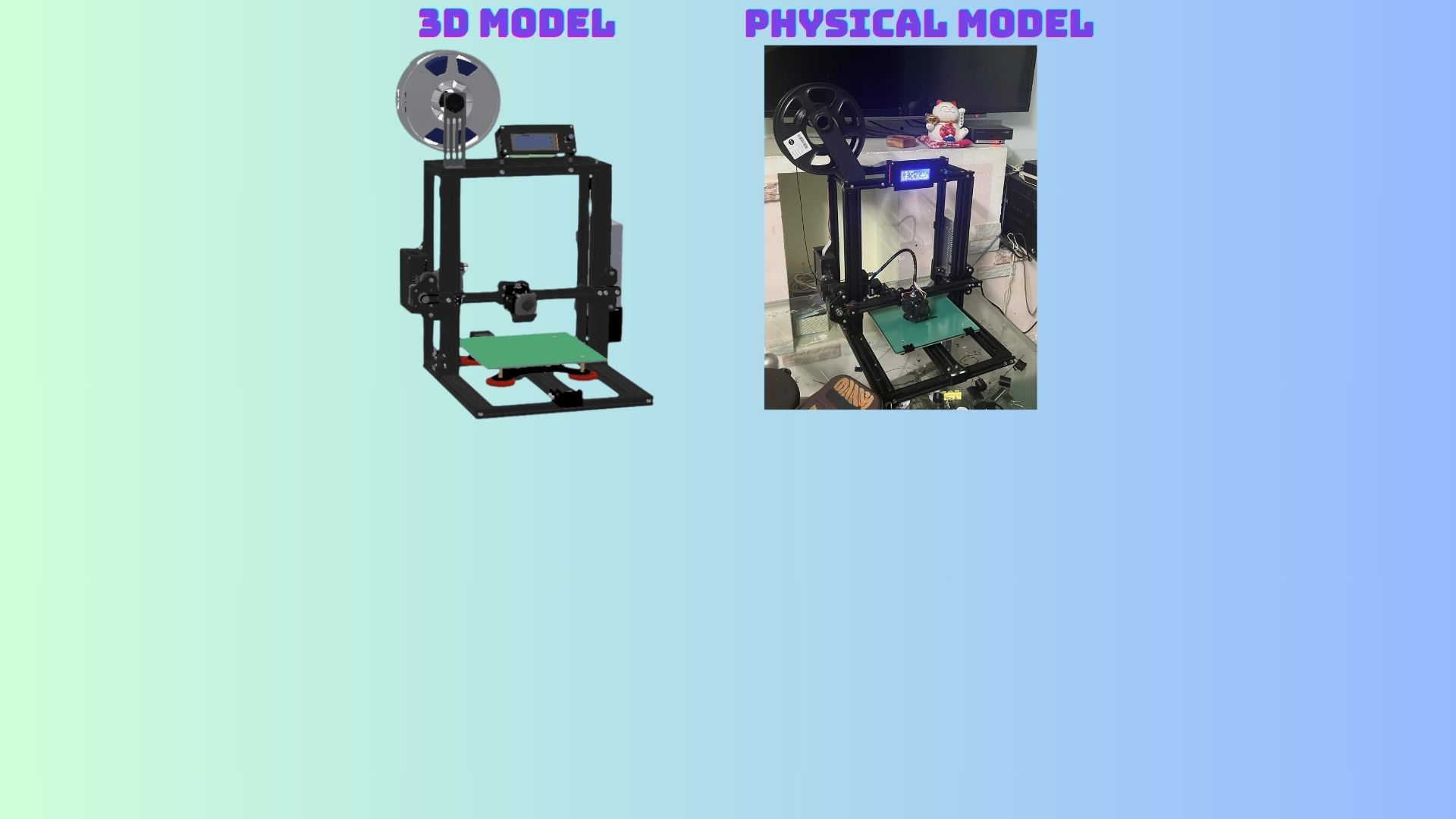

Step 1: SolidWorks modeling

Step 2: Start building the frame

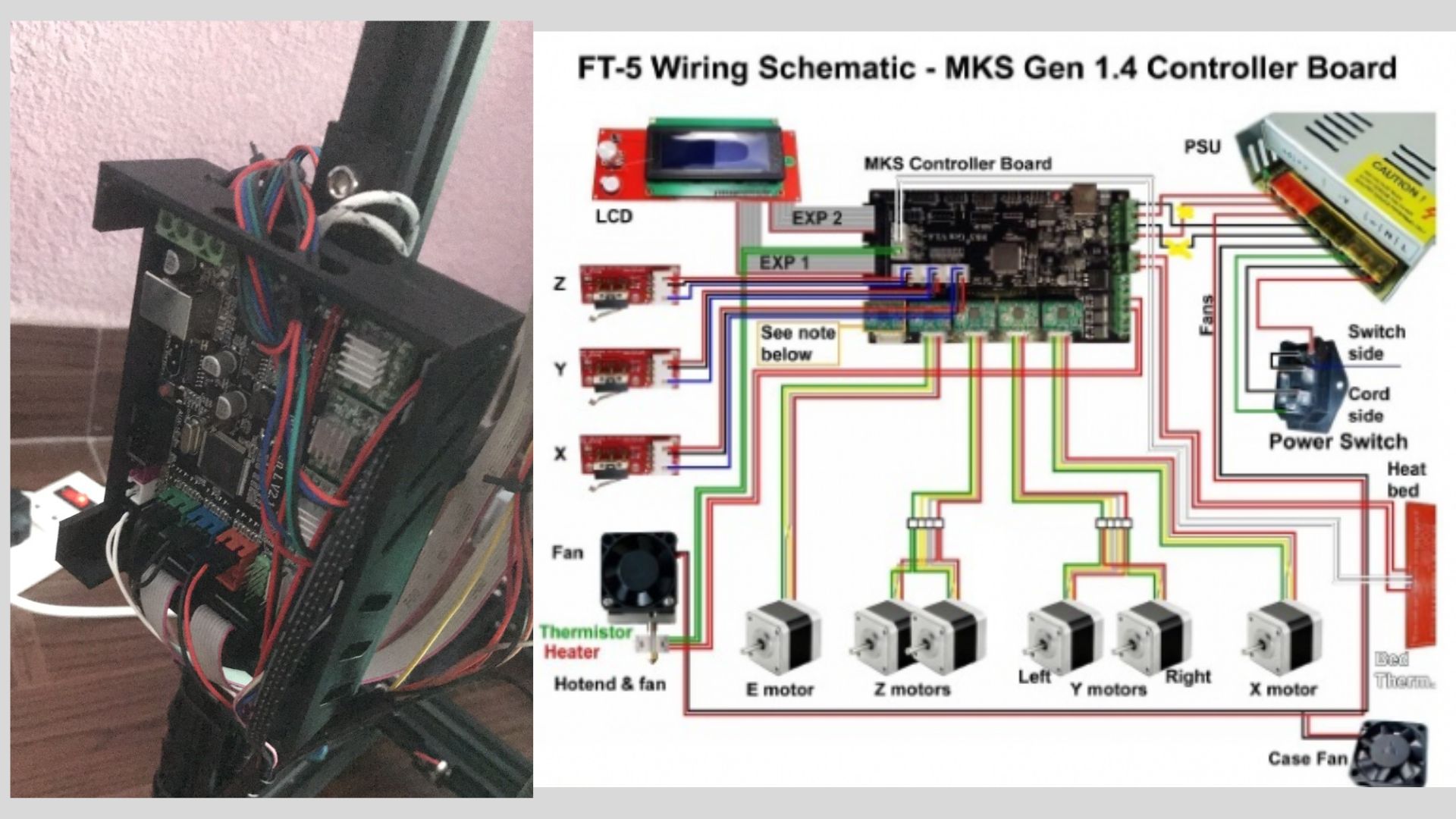

Step 3: Wiring

In this step, I need to wire these components:

- 1 stepper motor for X gantry

- 1 stepper motor for Y gantry

- 2 stepper motor for Z axis

- 1 thermomistor, 1 heater, 1 layer fan, 1 heatsink fan

- 3 mechanical endstops

- 1 LCD screen

- 1 PSU

Step 4: Configure and upload the firmware with C++

I used the Marlin firmware 1.1.9 which is the opernsource firmware for 3D printer. Although the firmware is already had, I still need to adjust some configuration to fit with my own hardware on my 3D printer such as:

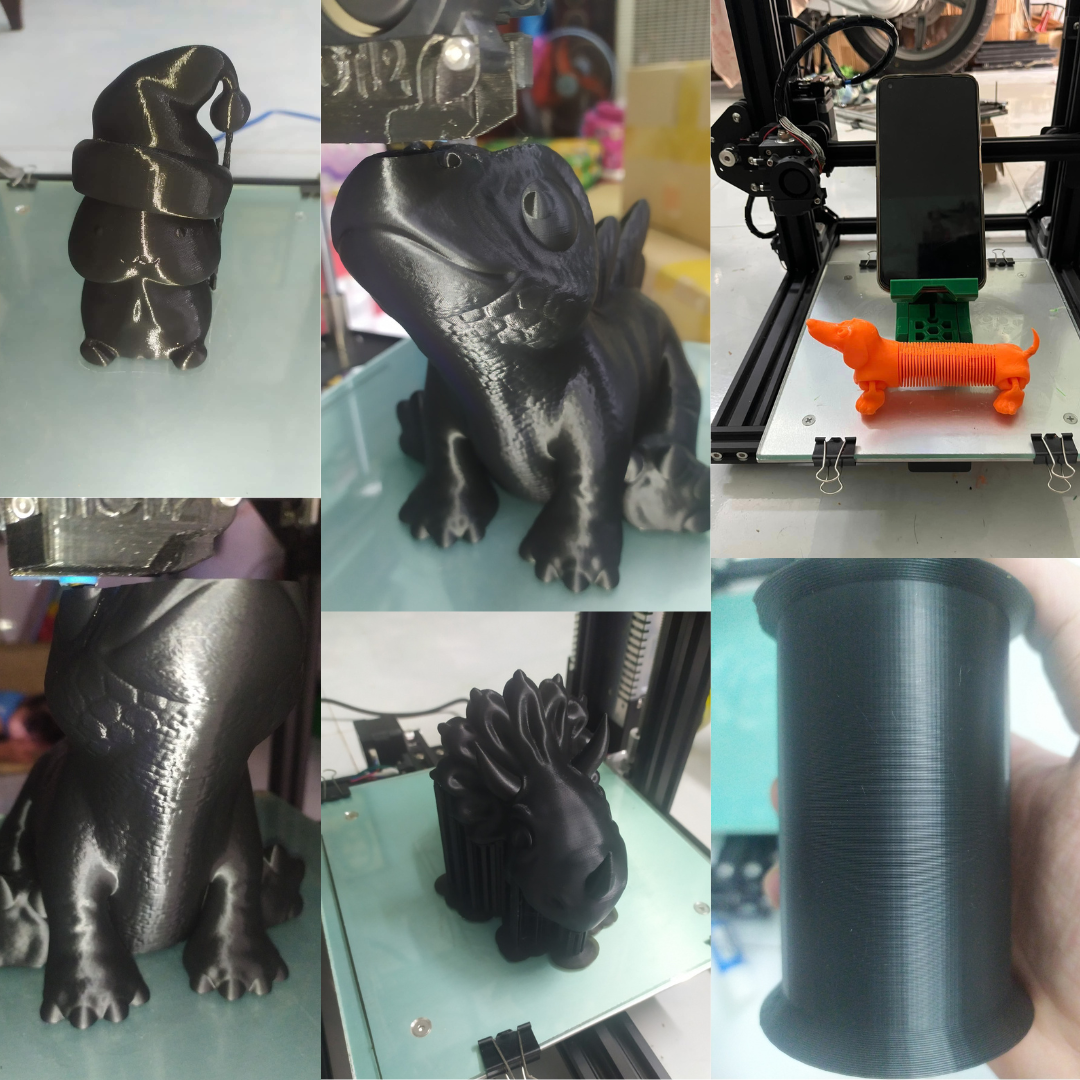

Final result